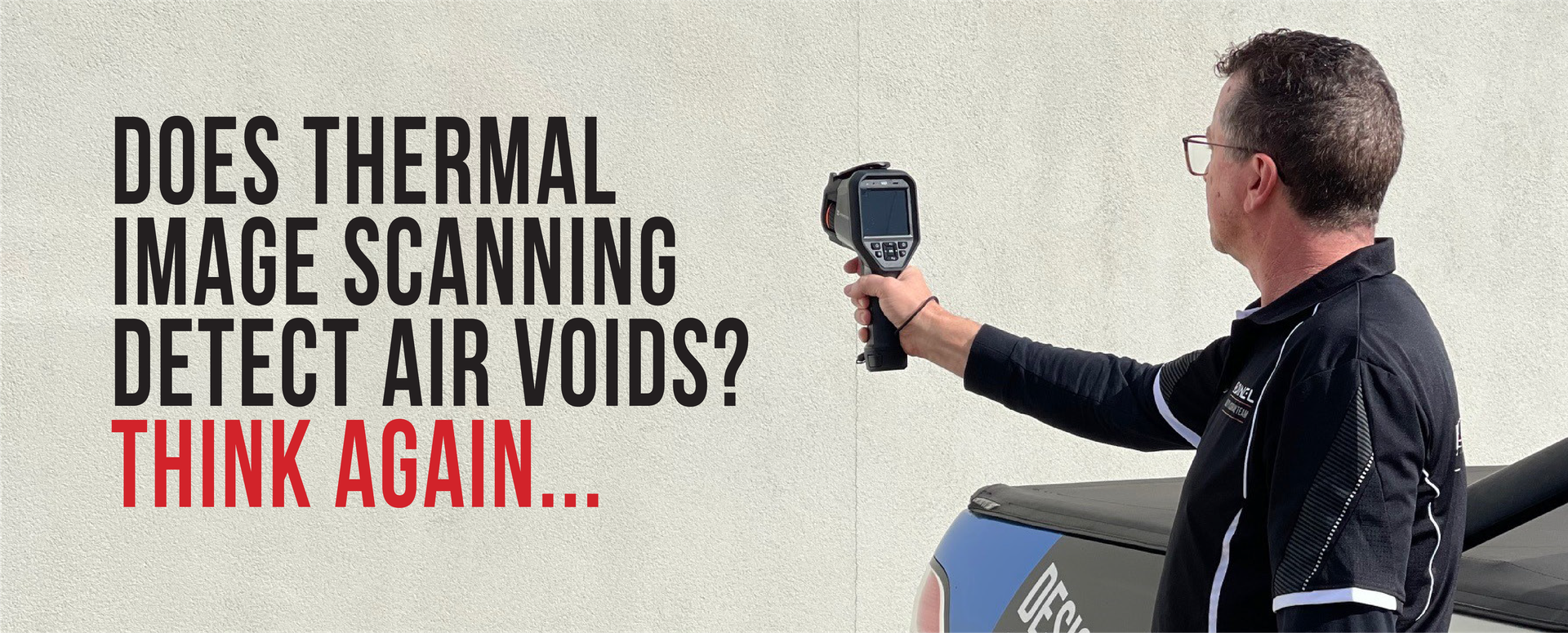

The fail-safe method for eliminating air voids in permanent formwork

Published 11 December 2020 | Download PDF Version

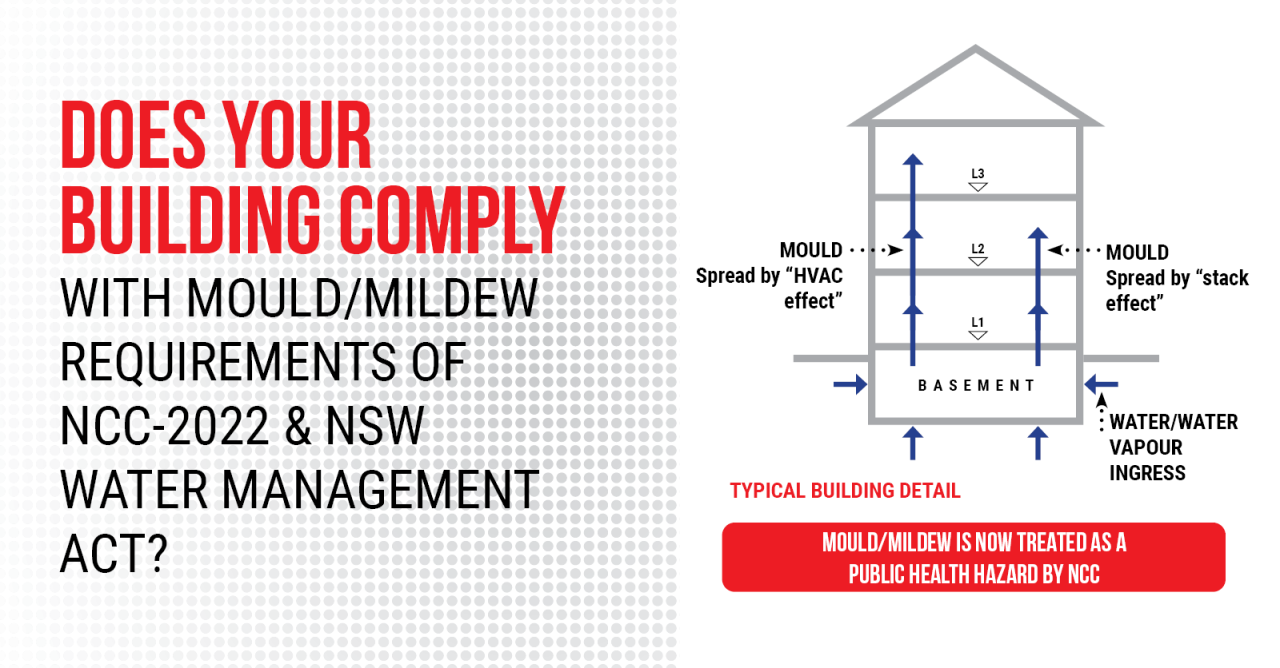

Designed to withstand the high pressures generated from the use of vibrators and high slump concrete, Dincel 275 ensures the elimination of air voids when the following is adopted:

1. High Slump Concrete

A minimum of 180mm concrete slump at the point of discharge, with a maximum aggregate size of 10mm, is required to ensure adequate flow through the formwork.

2. Use of Vibrators

A 25mm pocket vibrator with flexible shaft should be used. The vibrator should be lowered at regular intervals across the wall’s length, and moved up from the bottom of each pour/lift until clear of the concrete.

- Perforations within internal ring eliminates segregation by controlling and directing concrete flow.

- Internal ring resists concrete pour pressures allowing for high slump concrete (>240mm) or single lifts/pours up to 4.5m.

- Non-hygroscopic formwork material maximises concrete flow.

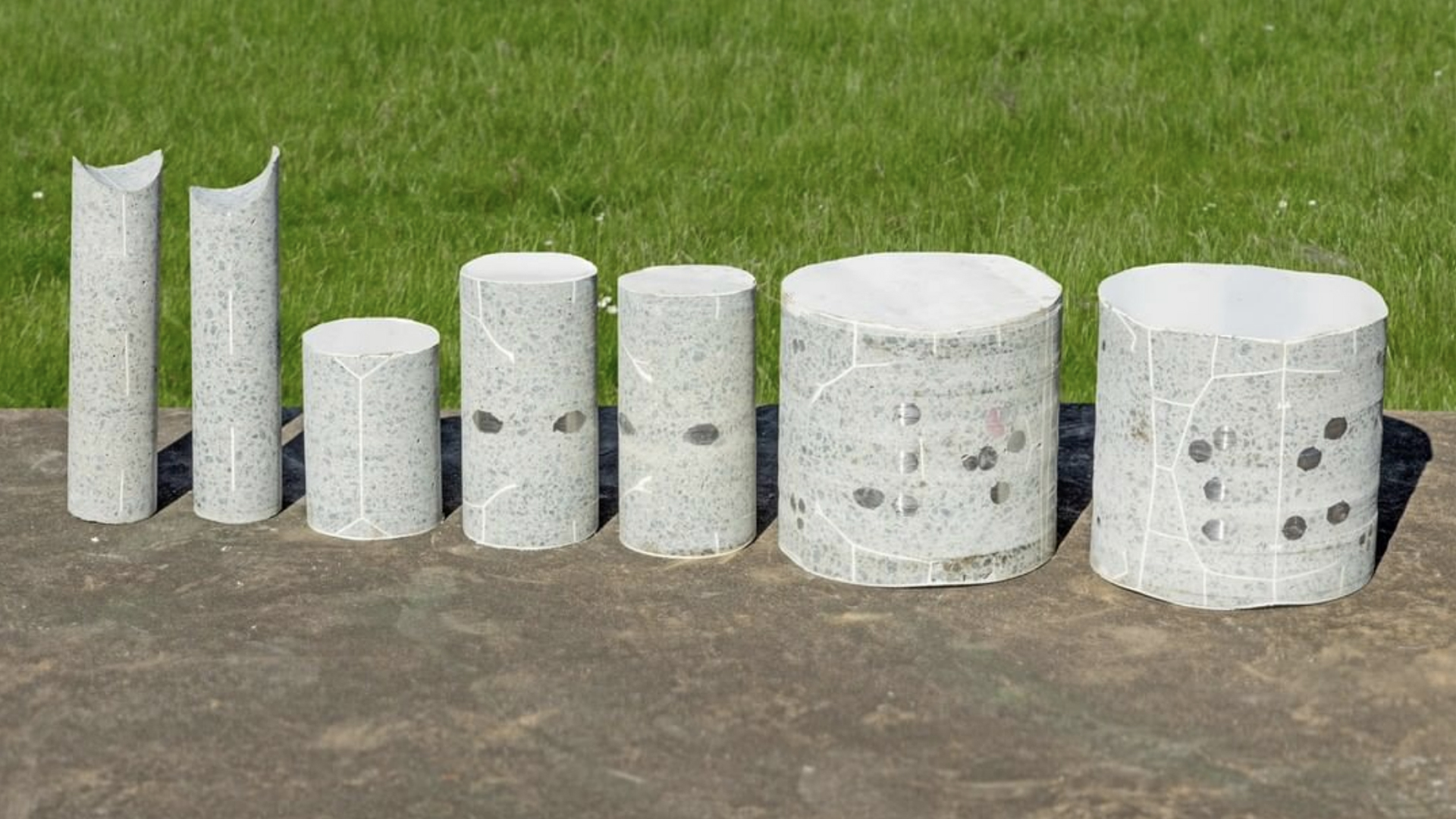

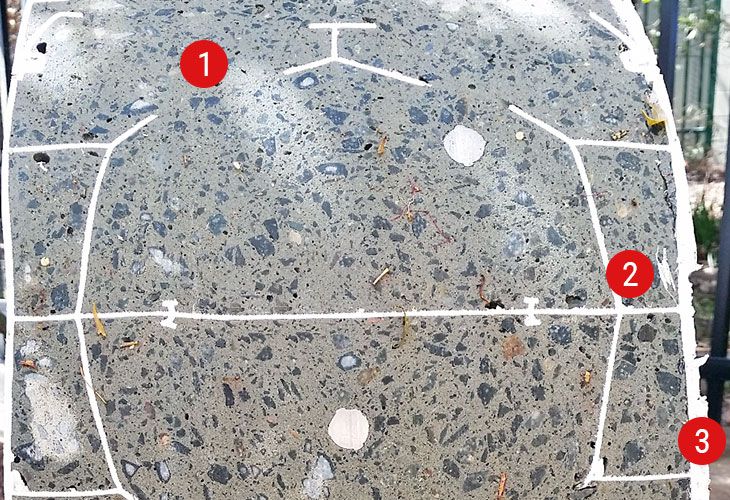

Concrete Quality Test

Core sample taken from Dincel 275 to demonstrate concrete quality within.

Gundagai Case Study

Dincel 275 used for a large retaining wall in a sewerage treatment plant.